This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- Info line: +39 0872 50841

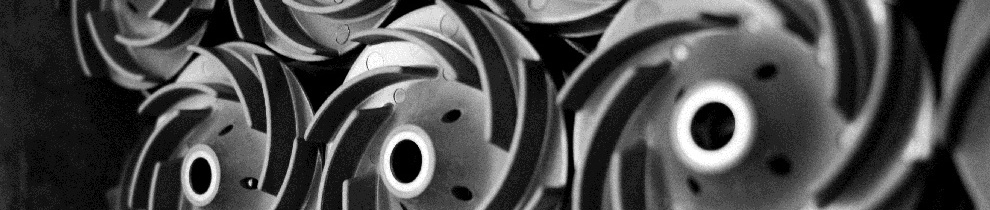

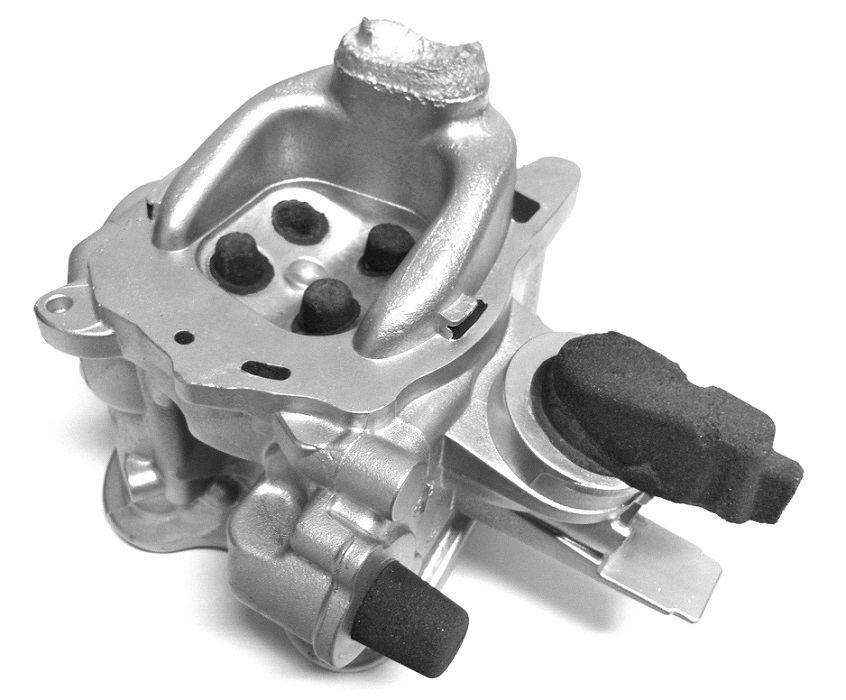

Low Pressure Casting and Gravity Casting:

They are processes in which the molten metal very slowly flows into the mold cavity. Produced castings will so obtain the best mechanical properties, minimal inclusions (air and impurities) and a very refined structural integrity. Both these shell methods can achieve aligned quality standards, therefore the choice for Compi depends on the requested volumes per year. We suggest Low Pressure for the high volumes due to its repeatability and a useful possibility to independently manage a multi-cavity system. Do you wonder why such a “slow” process in the fast-pace of the Automotive business? Well, fundamentally because we can implement cavities and/or draft angle surfaces on a whole piece part. The Sand Cores do that; we produce them internally, making sure that all the functional and aesthetical aspects are taken care of.

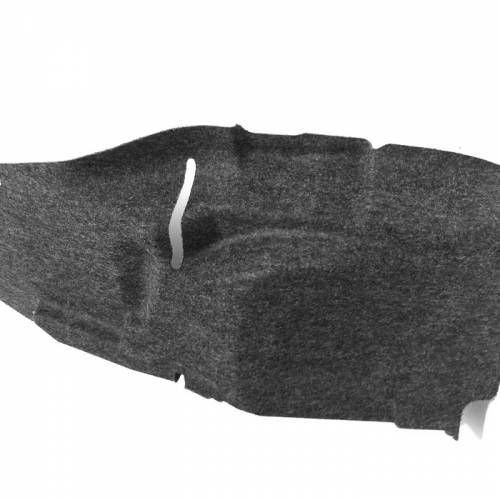

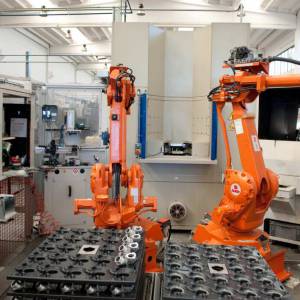

Finishing, Heat Treatments and Optional Processes:

Once out of the shell, our castings need more attentions than you think, before they respond to all customer requirements. We remove the sand core from castings in robotized isles, then we can choose the appropriate heat treatment and which oven matches the requested volume, so to reach the needed mechanical characteristics. The end line of the casting production is a manual finishing stage and overall check, one by one of all the parts. An additional sandblasting is usually offered in order to provide a unique casting that has to look like all the others!

Capacity:

Our total melting capacity is 1250 Kg/h. Then we put at disposal a Low Pressure production capacity of 16.200 Kg of castings per day. On the other hand, simple Gravity casting can reach the 3.600 Kg a day.

Features:

Compi have available both Gas Melting Ovens and Electrical Melting Ovens; this gives the possibility to handle different alloys at the same time and furthermore to refine each alloy composition when requested. All the production equipment, expecially the project customized ones, are entirely designed and manufactured by C.A.Stampi (Compi associated Tool Maker). The product first proposed by our customers, are always co-designed from the feasibility point of view, through Casting Simulations (QuikCast) and machining simulations. To guarantee the full functionality, when making the part feasible and hopefully cheaper, has always been a clear priority to Compi. The constant quality of what we sell is possible thanks to the many in-line controls (i.e.: dimensional, X-ray, Ultrasound probes, Penetrant liquids, etc.).