This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- Info line: +39 0872 50841

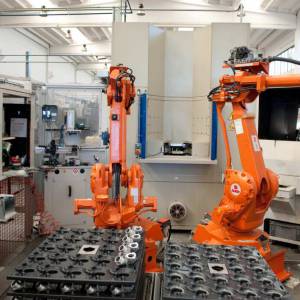

Robotized Lines:

The most significant assy line that Compi implemented was producing Nozzles for turbochargers (a key component for the variable geometry ones). The reached capacity was 6.000 Parts a day, also switching between different PNs and variants (made by the use of different components). The operations integrated in the full automatic line was: Plasma Welding, Press Fitting, Gluing, Bolting, etc.

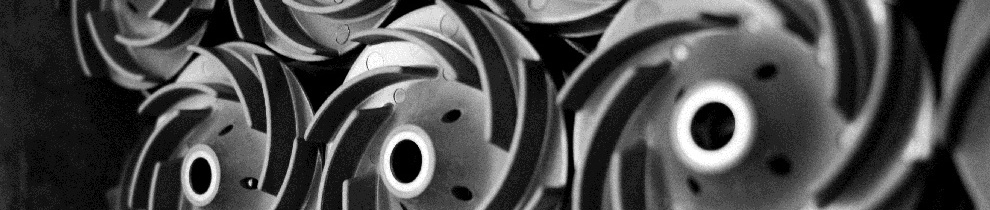

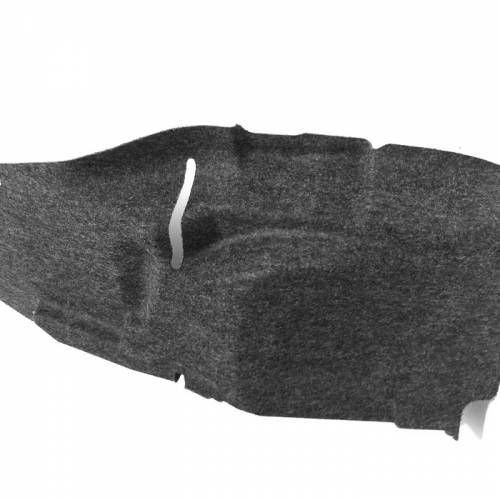

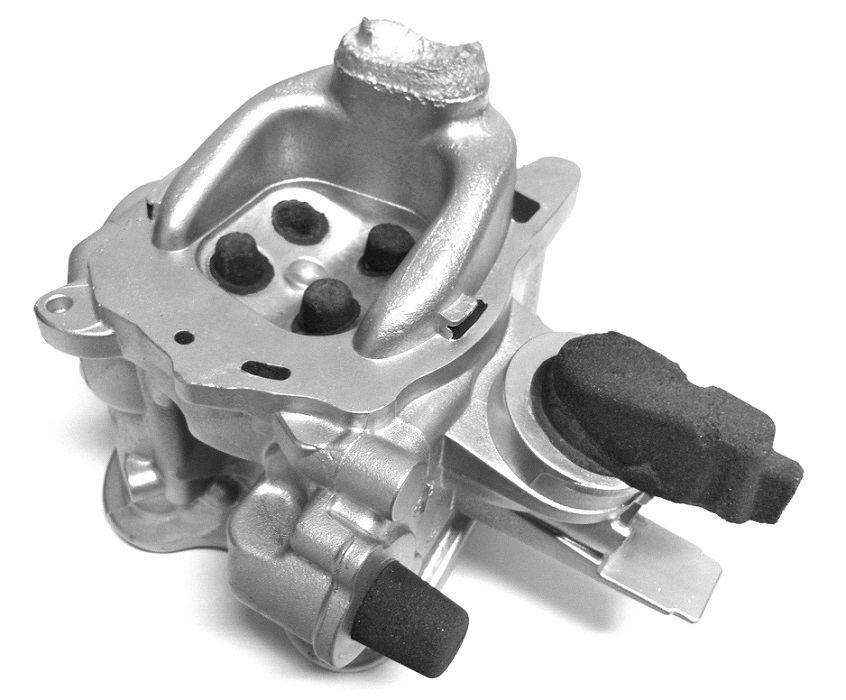

Sub-components:

Usually the turbo components that Compi produce, include small parts to be assembled. The many projects managed made us deal with Actuators, Position Pins, Screws, Plugs, Levers, Pipes, Valves, Sealings, etc.