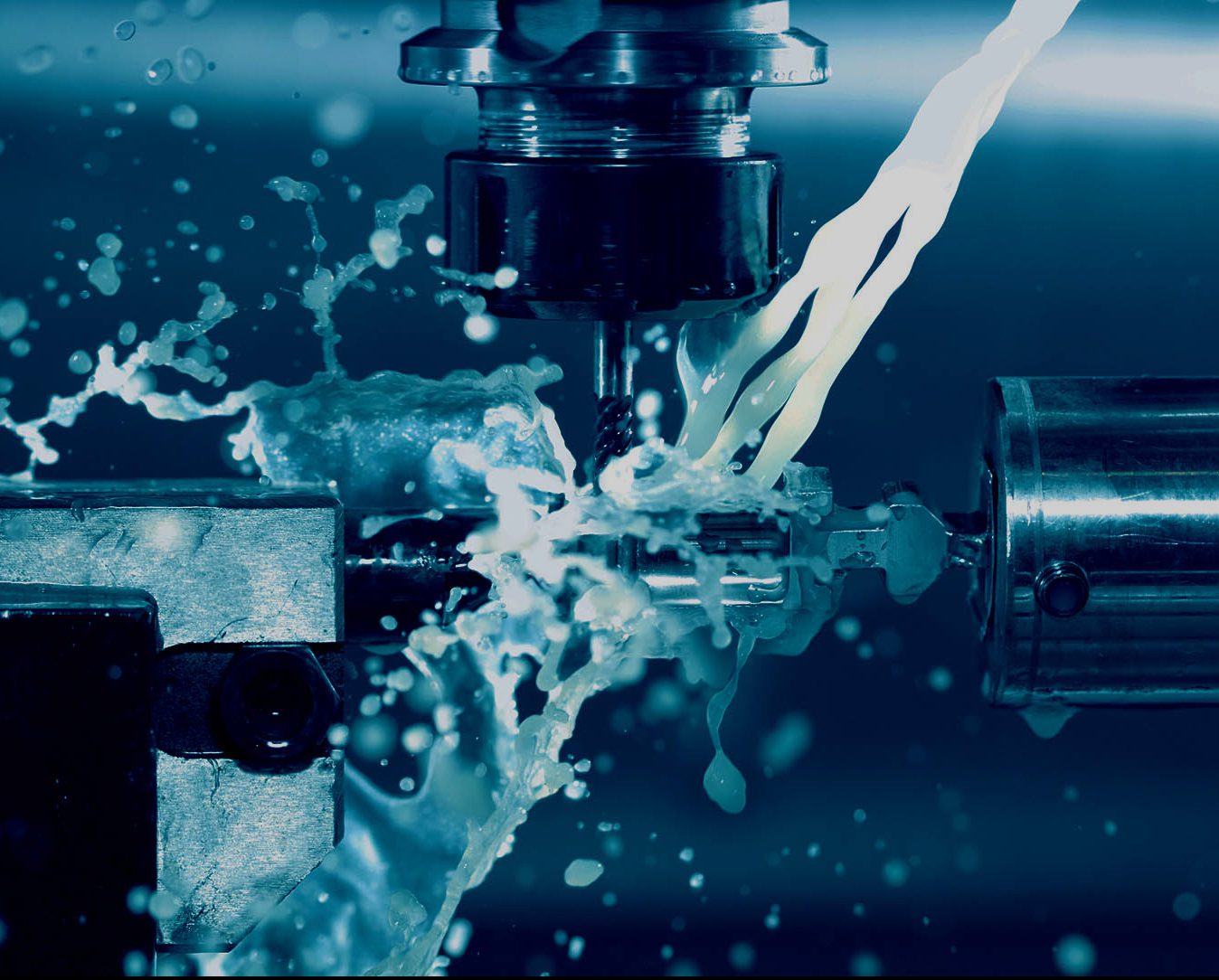

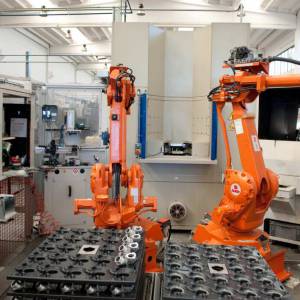

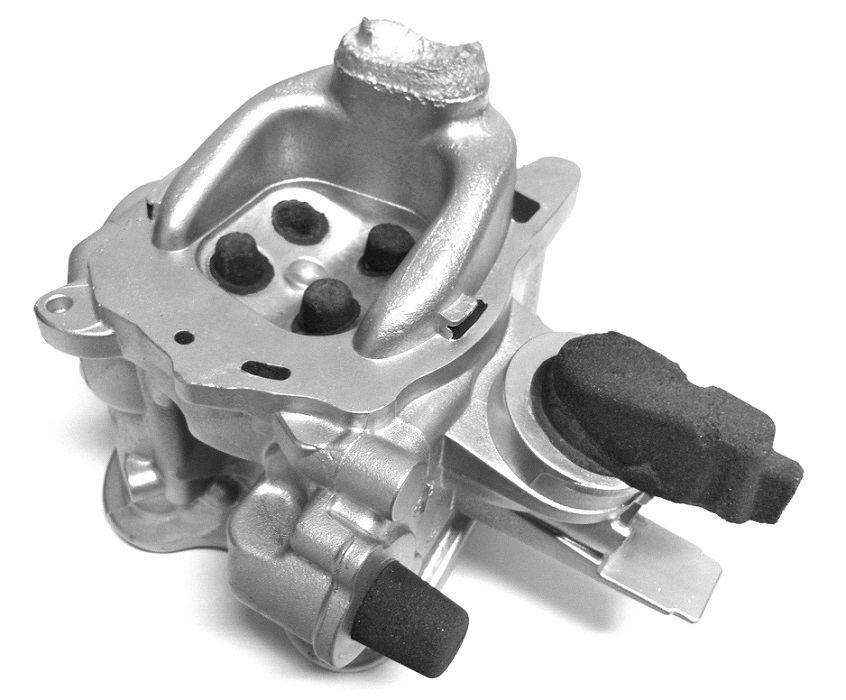

The gravity and low pressure castings are strongly recomended when high mechanical properties and quite complex shapes are the primary requirements. Compi foundry experience begun in 1997 and it is now a core business. Casting process have been made in these years extremely reliable.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.